Evaluación de mesófilos de lactosuero con actividad ácido láctica en medio con Canna indica L

Evaluation of lacto-serum mesophylls with lactic acid activity in medium with Canna indica L

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-CompartirIgual 4.0.

Mostrar biografía de los autores

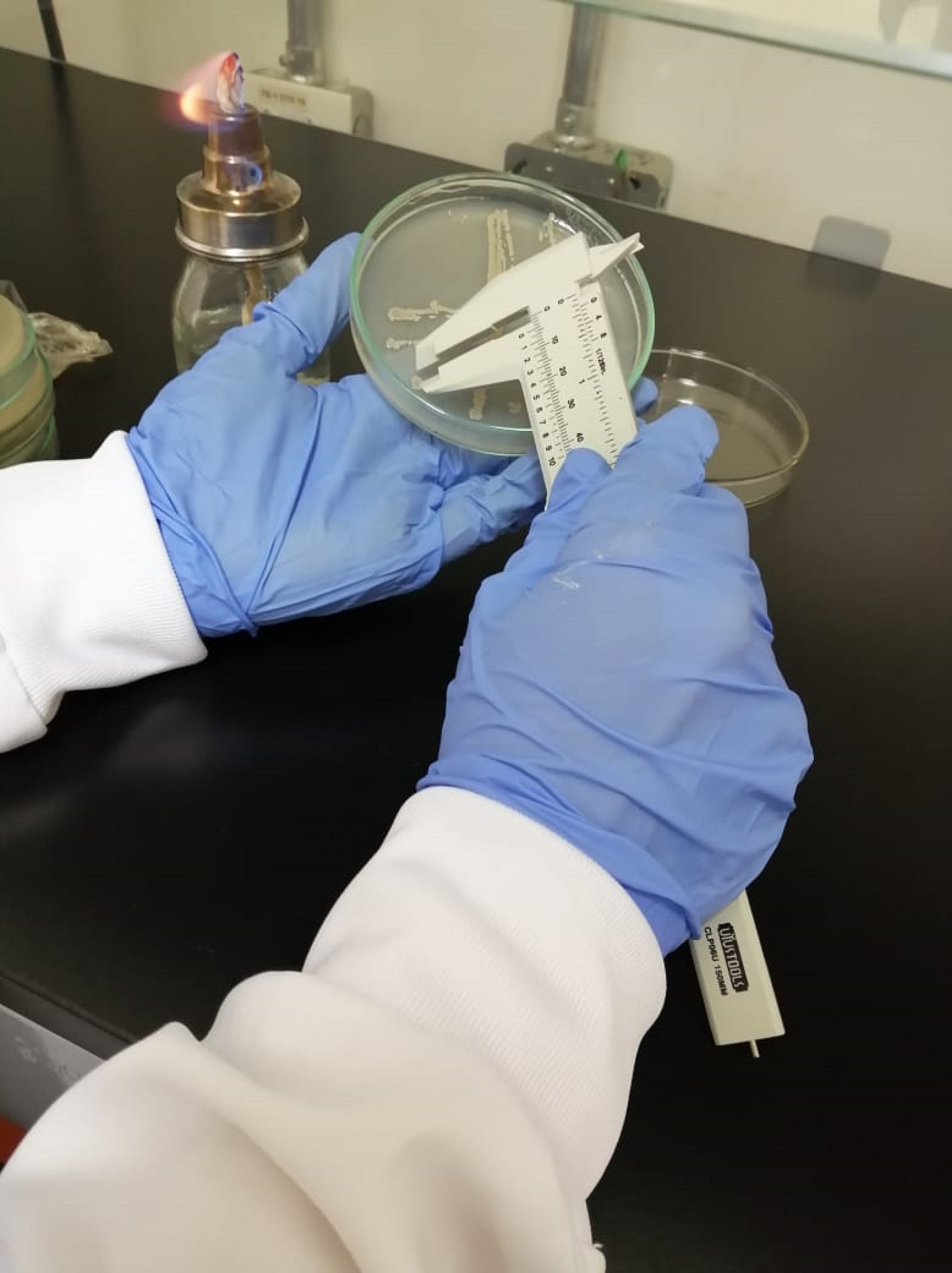

Objetivo. Evaluar lactosuero como fuente de mesófilos con actividad ácido láctica en medio de cultivo complejo con almidón de sagú (Canna indica L.). Materiales y métodos. Se analizaron tres medios de cultivo para bacterias mesófilas de lactosuero diferenciados por la inclusión de almidón de sagú (Canna indica L.) (0, 0.5 y 1%). Los tratamientos control fueron suero refrigerado (-4°C) y sin refrigerar (18°C). Se evaluó el crecimiento de mesófilos, pH, nivel de acidez, y sólidos solubles totales con intervalos de 24 h durante 5 días; y concentración de ácido láctico al finalizar el ensayo. Resultados. El pH y los sólidos solubles totales (°Brix) disminuyeron en todos los tratamientos, el porcentaje de acidez aumentó con el tiempo y al finalizar el ensayo el mayor contenido de ácido láctico fue de 32.5 y 37.2 g/L para las formulaciones con 0.5 y 1% de almidón de sagú respectivamente. El crecimiento de mesófilos fue bajo en la formulación con 1% de almidón y alto en el suero sin refrigerar. Conclusión. El lactosuero es una buena fuente de mesófilos con actividad ácido láctica lográndose hasta 37.2 g/L de ácido láctico en medio de cultivo complejo con inclusión de 1% de almidón de sagú.

Visitas del artículo 448 | Visitas PDF

Descargas

- Diaz-Vela J, Mayorga-Reyes L, Totosaus SA, Perez-Chabela MDL. Kinetic parameters and short-chain fatty acid profile of thermotolerant lactic acid bacteria with different carbon sources. Vitae. 2012; 19(3):253-260. https://revistas.udea.edu.co/index.php/vitae/article/view/11505

- Sarhan MS, Hamza MA, Youssef HH, Patz S, Becker M, Elsawey H, et al. Culturomics of the plant prokaryotic microbiome and the dawn of plant- based culture media - A review. J Adv Res. 2019; 19:15-27. https://doi.org/10.1016/j.jare.2019.04.002

- Zacarías-Sánchez KI, Rodríguez-Flores F, Luna-Jiménez AL, González-Cortés N, Jiménez-Vera R. Complex culture media for the quantification of lactic acid bacteria. Eur Sci J. 2019; 15(27):10-22. http://dx.doi.org/10.19044/esj.2019.v15n25p1

- Yong K, Hussin MH, Baidurah S. Biosynthesis of poly (3- hydroxybutyrate) (PHB) by Cupriavidus necator from various pretreated molasses as carbon source. Biocatal Agric Biotechnol. 2019; 17:51-59. https://doi.org/10.1016/j.bcab.2018.11.006

- Soupioni M, Psarologou A, Koutinas A. Revealing new promoters in whey fermentation leads to a new research concept. Heliyon. 2019; 5(2):1-15. https://doi.org/10.1016/j.heliyon.2019.e01262

- Salari M, Khiabani SM, Mokarram RR, Ghanbarzadeh B, Kafil SH. Preparation and characterization of cellulose nanocrystals from bacterial cellulose produced in sugar beet molasses and cheese whey media. Int J Biol Macromol. 2019; 122:280-288. https://doi.org/10.1016/j.ijbiomac.2018.10.136

- Brandelli A, Daroit JD, Corrêa AP. Whey as a source of peptides with remarkable biological activities. Food Res Int. 2015; 73:149-161. https://doi.org/10.1016/j.foodres.2015.01.016

- Khramtson, AG. New technological paradigm of the Russian dairy industry: Formation principles under globalization. Foods raw mater. 2019; 7(2):291-300. http://doi.org/10.21603/2308-4057-2019-2- 291-300

- Deep G, Hassan AN, Metzger L. Exopolysaccharides modify functional properties of whey protein concentrate. J Dairy Sci. 2012; 95(11):6332-6338. https://doi.org/10.3168/jds.2012-5649

- Johnson ME. A 100-Year Review: cheese production and quality. J Dairy Sci. 2017; 100(12):9952-9965. https://doi.org/10.3168/jds.2017-12979

- Parashar A, Jin Y, Mason B, Chae M, Bressler DC. Incorporation of whey permeate, a dairy effluent, in ethanol fermentation to provide a zero waste solution for the dairy industry. J Dairy Sci. 2016; 99(3):1859-1867. https://doi.org/10.3168/jds.2015-10059

- Cagri-Mehmetoglu A, Kusakli S, Venter M. Production of polysaccharide and surfactin by Bacillus subtilis ATCC 6633 using rehydrated whey powder as the fermentation medium. J Dairy Sci. 2012; 95(7):3643-3649. https://doi.org/10.3168/jds.2012-5385

- Reihani SFS, Khosravi-Darani K. Influencing factors on single-cell protein production by submerged fermentation: a review. Electron J Biotechnol. 2019; 37:34-40. https://doi.org/10.1016/j.ejbt.2018.11.005

- Garcés FR, Carbo JJ. First report of Puccinia thaliae in Canna spp. in Ecuador.Bioagro. 2013; 25(3):207-210. http://www.ucla.edu.ve/bioagro/Rev25(3)/9.%20MS%201307.pdf

- Fonseca-López D, Monroy-Fonseca L, Rodríguez-Molano CE. Effect of Canna indica L. starch extraction method on its physicochemical properties. Rev Lasallista Investig. 2019; 16(2):44-52. https://doi.org/10.22507/rli.v16n2a4

- Yi L, Boekel MAJS, Boeren S, Lakemond CMM. Protein identification and in vitro digestion of fractions from Tenebrio molitor. Eur Food Res Technol. 2016; 242:1285-1297. https://doi.org/10.1007/s00217-015-2632-6

- Rodríguez-Molano C, Fonseca-López D, Niño-Monroy LE, Salamanca-López AE, Hoyos-Concha JL, Otero-Ramírez ID, Torres- Lagos N. Nutritional characterization and biomass production of Sambucus peruviana, Sambucus nigra and Morus alba in a forage bank. Ciencia en Desarrollo. 2019; 10(2):23-32. https://doi.org/10.19053/01217488.v10.n2.2019.9098

- Fonseca-López D, Saavedra-Montañéz G, Rodríguez-Molano CE. Elaboration of a carrot (Daucus carota L.) based cattle feed by solid- state fermentation as an eco-efficient alternative. Revista Colombiana de Ciencias Hortícolas. 2018; 12(1):175-182. https://doi.org/10.17584/rcch.2018v12i1.7416

- Figueira ACM, Rocha JBT. A proposal for teaching undergraduate chemistry students carbohydrate biochemistry by problem-based learning activities. Biochem Mol Biol Educ. 2013; 42(1):81-87. https://doi.org/10.1002/bmb.20745

- Kim M, Seo JA. Fermentation profiling of rice wine produced by Aspergillus oryzae KSS2 and Rhizopus oryzae KJJ39 newly isolated from Korean fermentation starter. Appl Biol Chem. 2021; 64(25):1-7. https://doi.org/10.1186/s13765-020-00582-2

- Besir A, Yazici F, Mortas M, Gul O. A novel spectrophotometric method based on Seliwanoff test to determine 5-(Hydroxymethyl) furfural (HMF) in honey: Development, in house validation and application. LWT. 2021; 139:1-8. https://doi.org/10.1016/j.lwt.2020.110602

- Pawar HA, Gavasane AJ, Choudhary PD. Extraction of polysaccharide from fruits of Cordia dichotoma G. Forst using acid precipitation method and its physicochemical characterization. Macromolecules. 2018; 115:871-875. https://doi.org/10.1016/j.ijbiomac.2018.04.146

- Fonseca-López D, Rodríguez-Molano CE. Effect of a microbial inoculant on the microbiological and nutritional quality of Morus alba L. and Sambucus nigra L. silage. J Logos Cienc Tecnolog. 2019; 11(2):93-101. https://doi.org/10.22335/rlct.v11i2.825

- Zou Y, Wang Y, Deng Y, Cao Z, Li S, Wang J. Effects of feeding untreated, pasteurized and acidified waste milk and bunk tank milk on the performance, serum metabolic profiles, immunity, and intestinal development in Holstein calves. J Anim Sci Biotechnol. 2017; 8(1):1-11. https://doi.org/10.11 86/s40104-017-0182-4

- Miranda-Yuquilema J, Marin-Cárdenas A, Valle-Cepeda A, Barros- Rodríguez M, Marrero-Suárez L, Hidalgo-Almeida L, Rivera-Guerra V. Wastes of agroindustry an alternative to develop biopreparates with probiotic capacity. Trop Subtrop Agroecosystems. 2018; 21(1):46-52. https://www.revista.ccba.uady.mx/ojs/index.php/TSA/article/view/25 99/1111

- Ali AH. Current knowledge of buttermilk: Composition, applications in the food industry, nutritional and beneficial health characteristics. Int J Dairy Technol. 2019; 72(2):169-182. https://doi.org/10.1111/1471-0307.12572

- Zhang S, Wang J, Jiang H. Microbial production of value-added bioproducts and enzymes from molasses, a by-product of sugar industry. Food Chem. 2021; 346:1-14. https://doi.org/10.1016/j.foodchem.2020.128860

- Fonseca-López D, Vivas-Quila NJ, Balaguera-López HE. Techniques applied in agricultural research to quantify nitrogen fixation: a systematic review. Cienc Tecnol Agropecuaria. 2019; 21(1):1-19. https://doi.org/10.21930/rcta.vol21_num1_art:1342

- Bahry H, Abdalla R, Pons A, Taha S, Vial Ch. Optimization of lactic acid production using immobilized Lactobacillus Rhamnosus and carob pod waste from the Lebanese food industry. J Biotechnol. 2019; 20:81-88. https://doi.org/10.1016/j.jbiotec.2019.09.017

- Bernardo MP, Coelho LF, Sass DC, Contiero J. l-(+)-Lactic acid production by Lactobacillus rhamnosus B103 from dairy industry waste. Braz J Microbiol. 2016; 47(3):640-646. https://doi.org/10.1016/j.bjm.2015.12.001